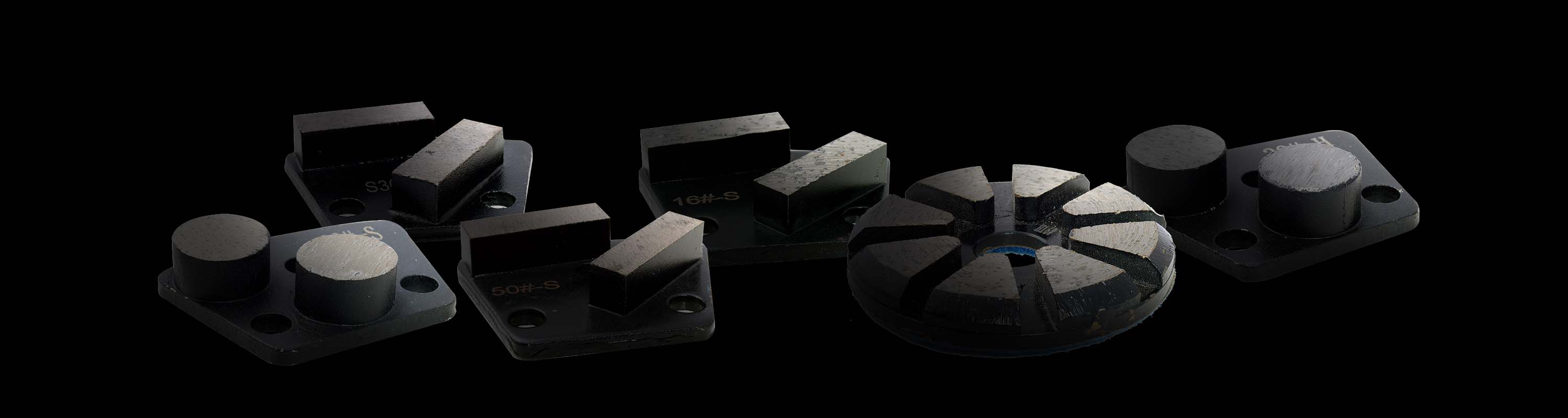

Metal Bond Tooling

SERIES 37 – Metal Bond Tooling

Series 37 – 2 Bar Trapezoid Tooling

Description

The 37 Series 2 Bar Trapezoid tooling is a proprietary matrix of top quality abrasive diamonds embedded evenly throughout both segments. The rectangular segments are designed for aggressive scratching and exceptional durability with strong grinding capabilities. The metal segments are designed for wet or dry applications. The manufacturing process ensures even distribution of abrasives throughout the tool adding to the longevity and performance of the tooling.

Uses

The 37 Series 2 Bar Trapezoid tooling is an excellent diamond tool generally used in the first few steps of the concrete polishing process and as an ideal mechanical preparation tool on concrete for cementitious overlays and industrial coatings. Depending on the surface coating, the 2 Bar Trapezoid can be used as a coatings removal tool up to 1mm thick while not gouging the surface. The rugged design of the tool makes it ideal for heavy grinding, cutting and leveling especially when aggressive grinding is necessary.

Application

The 37 Series 2 Bar Trapezoid tooling is intended to be used on most concrete surfaces. It is recommended to use a hard bond matrix when the tooling is being used on medium to soft surfaces while the soft bond matrix is ideal on hard to very hard surfaces. The use of water in the grinding process will typically increase the life of the tooling as well as provide a more aggressive grind on the surface. It is highly recommended to use a vacuum system when dry grinding as this tooling will create large amounts of dust. 300-600 RPM’s is recommended. Do not exceed 1,000 RPM’s.

Thickness

8 MM

Size Available

3″ x 2″ Trapezoid (3 Hole Magnetic)

Grits Available in both Hard and Soft Bond

| 16 | 30 | 50 |

Coverage Rates

5,000 – 10,000 square feet

** Coverage can vary from surface to surface depending on roughness, porosity and density of the medium being applied. Application technique can also vary the coverage. Wet grinding will usually extend the life of the tooling.

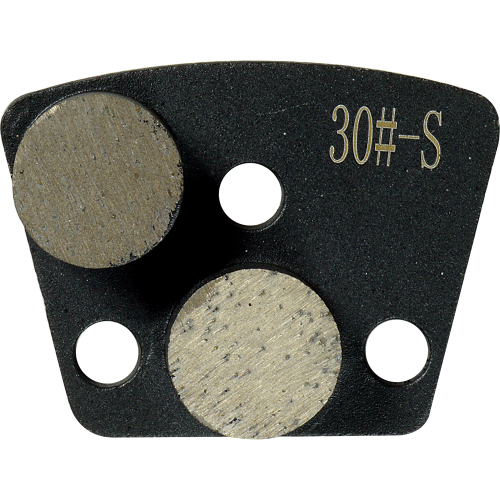

Series 37 – 2 Button Trapezoid Tooling

Description

The 37 Series 2 Button Trapezoid tooling is a proprietary matrix of top quality abrasive diamonds embedded evenly throughout both segments. The circular segments are designed for aggressive scratching and exceptional durability with strong grinding capabilities. The metal segments are designed for wet or dry applications. The manufacturing process ensures even distribution of abrasives throughout the tool adding to the longevity and performance of the tooling.

Uses

The 37 Series 2 Button Trapezoid tooling is an excellent diamond tool generally used in the first few steps of the concrete polishing process and as an ideal mechanical preparation tool on concrete for cementitious overlays and industrial coatings. Depending on the surface coating, the 2 Button Trapezoid can be used as a coatings removal tool up to 1mm thick while not gouging the surface. The rugged design of the tool makes it ideal for heavy grinding, cutting and leveling especially when aggressive grinding is necessary.

Application

The 37 Series 2 Button Trapezoid tooling is intended to be used on most concrete surfaces. It is recommended to use a hard bond matrix when the tooling is being used on medium to soft surfaces while the soft bond matrix is ideal on hard to very hard surfaces. The use of water in the grinding process will typically increase the life of the tooling as well as provide a more aggressive grind on the surface. It is highly recommended to use a vacuum system when dry grinding as this tooling will create large amounts of dust. 300-600 RPM’s is recommended. Do not exceed 1,000 RPM’s.

Thickness

8 MM

Size Available

3″ x 2″ Trapezoid (3 Hole Magnetic)

Grits Available in both Hard and Soft Bond

| 16 | 30 | 50 |

Coverage Rates

5,000 – 10,000 square feet

** Coverage can vary from surface to surface depending on roughness, porosity and density of the medium being applied. Application technique can also vary the coverage. Wet grinding will usually extend the life of the tooling.

Series 37 – 8 Segment Tooling

Description

The 37 Series 8 Segment tooling is a proprietary matrix of top quality abrasive diamonds embedded evenly throughout each segment. Rounded front edge is designed for minimal scratching, longer life and exceptional durability with strong grinding capabilities. The metal segments are designed for wet or dry applications while the 8 segment face design provides the best channeling for dust or slurry.

Uses

The 37 Series 8 Segment is an excellent diamond tool generally used in the first few steps of the concrete polishing process. Depending on the surface coating, the 8 Segment Tooling can be used as a coatings removal tool up to 1mm thick (16 grit is ideal) while not gouging the surface. The rugged design of the tool makes it ideal for heavy grinding, cutting and leveling especially when aggressive grinding is necessary.

Application

The 37 Series 8 Segment tooling is intended to be used on most concrete surfaces. It is recommended to use a hard bond matrix when the tooling is being used on medium to soft surfaces while the soft bond matrix is ideal on hard to very hard surfaces. The use of water in the grinding process will typically increase the life of the tooling as well as provide a more aggressive grind on the surface. It is highly recommended to use a vacuum system when dry grinding as this tooling will create large amounts of dust. 300-600 RPM is recommended. Do not exceed 1,000 RPM’s.

Thickness

6 MM

Diameters Available

3″ – (Hook and Loop / 3 Hole Magnetic)

5″ – (Hook and Loop ONLY)

Grits Available in both Hard and Soft Bond

| 16 | 30 | 50 |

Coverage Rates

15,000 – 40,000 square feet