Maintenance and/or Burnishing Pads

Series 40 – Hurricane Pads

Description

The 40 Series Hurricane Pads are designed for durability and longevity for a wide variety of applications. They have diamond powder blown throughout the entire pad creating a stronger, wear and tear resistant pad at an economical price. The diamond powders provided extended life due to the ability to use either side creating a stronger, more durable tool for most flooring situations.

Uses

The 40 Series Hurricane Pads are primarily used a burnishing pad for high speed burnishing machines to create the heat needed in the application of most guards or sealers specified in concrete polishing. The versatility and diamond coating in the pad also make it the ideal tool for cleaning and/or maintaining floors of most types including VCT, natural stone, polished concrete, honed and densified concrete, terrazzo (cementitious and epoxy) as well as any sealed surface.

When used in a regular maintenance program the Hurricane Pad is extraordinary. The pads may be used wet or dry and are available in virtually any diameter to meet most maintenance machines including low speed swing machines, high speed burnishing machines, orbital machines, walk behind and ride on auto-scrubbers. The materials hold up well to harsh chemicals including mild acids used to etch floors. The variety of grits available makes it an ideal pad for scrubbing and buffing all types of flooring.

Application

The 40 Series Hurricane Pad is ideal for burnishing, cleaning, refurbishing, buffing, and maintaining concrete and terrazzo as well as restoration and maintenance on natural stone floors of all types. The 5” is used by many countertop fabricators to clean, buff and finish many varieties of countertops.

Thickness

1 inch

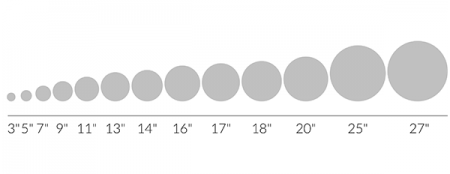

Diameters Available

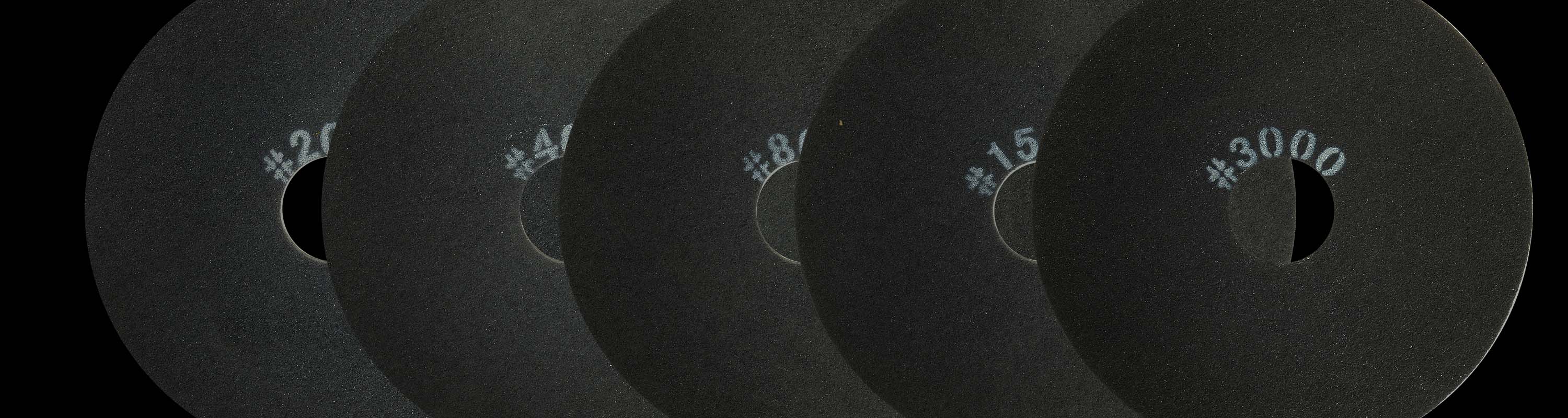

Grits Available

| 200 | 400 | 800 | 1500 | 3000 |

Coverage Rates

40,000 – 60,000 square feet